Plant OTR Tyre Sealant

The harshest of operating environments will understandably leave plant OTR tyres exposed to punctures – typically across construction & civil engineering; quarries, mining & aggregate industries; waste & recycling management sites and agricultural facilities. Here, Proplant Tyre Services recommend plant OTR Tyre Sealant as a proactive maintenance procedure that will reduce avoidable downtime and operating cost.

Plant OTR Tyre Sealant

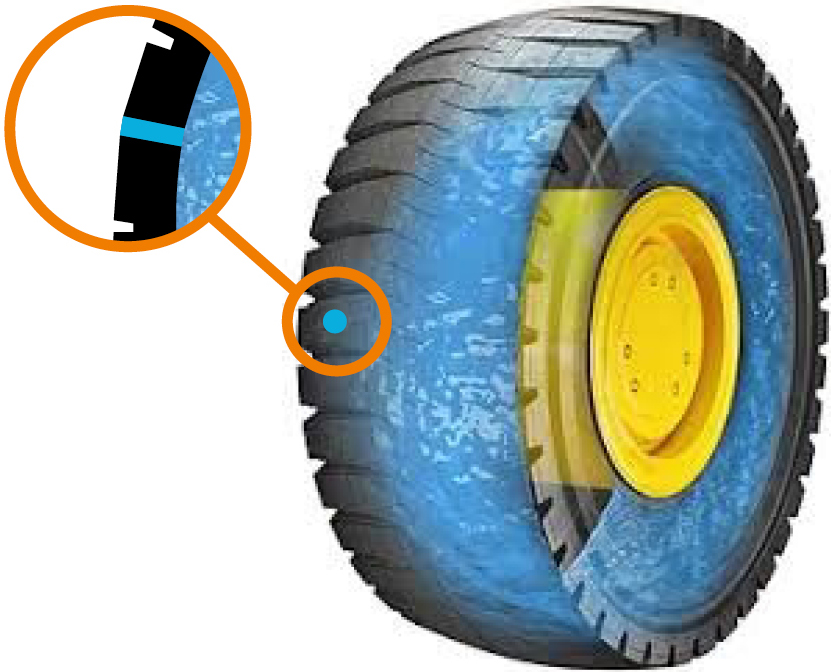

Proplant Tyre Services only use premium OTR Tyre Sealant that has been thoroughly tested and proven worldwide. The sealant is formulated from active water-based liquids, microscopic rubber crumb and Kevlar particles, fibres and powders that always remain in suspension. A small volume of sealant is injected through the valve into the tubeless tyre or innertube, which displaces a small amount of air in the process.

How tyre sealant works

As the tyre rotates, the high pressure that is generated forces the tyre sealant against the casing. Should a puncturing object create a piercing hole, the pressure immediately drives the liquid sealant into the hole. On contact with external air, the sealant instantaneously bonds with the tyre rubber to form a flexible but incredibly durable solid seal – on holes and slits of up to 20mm.

Tyre pressure and routine maintenance

Tyre pressure correction can still be performed to your machinery. When the wheel is stationery there is no pressure to propel the liquid sealant through the valve. Should tyre rotation or any other tyre maintenance be required, Proplant Tyre Services can remove the sealant by simply washing with water.

Tyre Sealant is proven to prevent punctures and maximise machine uptime in your operation.

Our skilled tyre professionals provide class-leading OTR tyre maintenance and repairs to all types of heavy plant machinery

Contact Us

Tyre Maintenance and Repairs

07805 096885

service@proplanttyres.co.uk

Multi-brand Tyre Sales

Please email

sales@proplanttyres.co.uk

Monday to Friday 8:00am to 5:30pm